Standpipe Hose System Inspection Form: Downloadable & Ready-to-Use

Standpipes are a key part of your fire protection system in your building, where firefighters can get water to fight fires. Inspecting, testing and maintaining these systems is critical to their readiness and fire safety standards. This guide will cover everything you need to know about standpipe system inspections: types of systems, testing and best practices for these fire protection systems.

Standpipe Systems

What is a Standpipe System?

A standpipe system is a network of pipes installed in a building to provide water for firefighting. These systems have hose connections or outlets at various locations so firefighters can connect their hoses and get water.

Standpipe systems are classified into three types:

- Class I: For fire departments and trained personnel, these systems have 2.5” hose connections.

- Class II: For building occupants, these systems have 1.5” hose connections and usually have hoses.

- Class III: A combination of Class I and Class II systems, has both 2.5” and 1.5” hose connections.

Types of Standpipe Systems

Standpipe systems are further classified based on water supply and activation:

- Automatic Wet: Always filled with water and ready to use.

- Automatic Dry: Filled with compressed air, water is released into the system when activated.

- Manual Wet: Filled with water but requires manual activation to pressurize the system.

- Manual Dry: Has no water, requires manual activation to fill the system with water.

Inspect, Test, Maintain Standpipes

What is a Standpipe Inspection?

A standpipe inspection is a thorough examination of the system’s components to make sure they are in working order. This includes:

- Visual Inspection: Look for any visible damage, leaks or obstructions in the system.

- Valve Status Test: Make sure all control valves are in the correct position and working.

- Flow Test: Verify the system can deliver the required water flow and pressure to all hose connections.

- Pressure Reducing Valve: Test and adjust pressure reducing valves to ensure they maintain the correct pressure.

Why Inspect Regularly

Regular inspections are important for:

- System Readiness: Inspections ensure the system is working and ready to use in an emergency.

- Compliance: Adhering to NFPA (National Fire Protection Association) standards, specifically NFPA 25, is fire safety compliance.

- Preventive Maintenance: Regular inspections help detect and address issues before they become system failures.

How Often to Inspect?

Standpipes should be inspected regularly. NFPA 25 specifies the inspection frequencies:

- Monthly: Visual inspection of control valves and pressure gauges.

- Quarterly: Inspection of alarm devices and waterflow alarms.

- Annually: Complete inspection of all components, including hoses, hose connections and fire department connections.

NFPA Standard for Standpipe and Hose Systems

Standpipe and hose systems are governed by NFPA 14, the Standard for the Installation of Standpipe and Hose Systems. This standard provides the guidelines for design, installation and maintenance of standpipe systems to ensure they are reliable and effective in providing fire protection.

Flow Test Requirements for Standpipes

Flow tests are part of standpipe system inspections. These tests ensure the system can deliver the required water flow and pressure to fight fires. The requirements for flow tests are:

- Frequency: Flow tests should be done annually to verify the system is working.

- Test Procedure: Water is discharged from the most distant hose valve outlet to measure the flow and pressure.

- Required Flow: The system must meet the minimum flow and pressure requirements in NFPA 25.

Key Components and Inspections

Fire Department Connections (FDCs)

Fire department connections are used to supplement the water supply to standpipe systems during a fire. Inspect to make sure FDCs are accessible, clear of obstructions and marked.

Hose Connections and Valves

Hose connections and valves should be inspected for leaks, damage and operation. This includes checking for proper threading and making sure caps and gaskets are in place.

Pressure Reducing Valves

Pressure reducing valves control the water pressure in the system to prevent damage to hoses and equipment. Test and adjust as needed to maintain the correct pressure.

Fire Pump Assemblies

Fire pump assemblies are used to provide the water pressure to standpipe systems. Inspect to make sure fire pumps are working and can deliver the required flow and pressure.

Remote Hose Valve Outlet

Remote hose valve outlets are used to supply water to remote or hard to reach areas. Inspect to make sure these outlets are working and accessible.

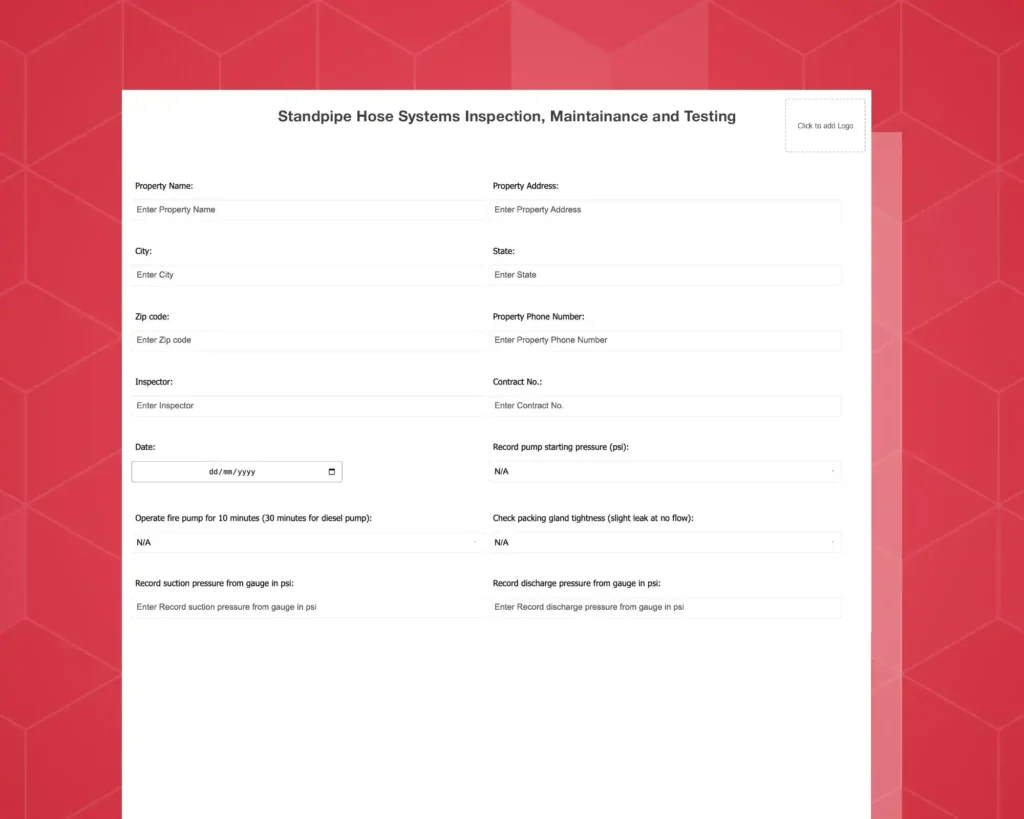

Documentation: 2017 Standpipe and Hose Inspection Form

Documentation of standpipe system inspections is critical to comply with NFPA standards and to ensure the system is reliable. The 2017 standpipe and hose inspection form is a complete form to record the inspection details. It includes:

- System Info: Standpipe system information, installation date and manufacturer.

- Inspection Date: Date of inspection and inspector’s name.

- Component Check: Detailed check of system components, valves, pressure gauges and fire department connections.

- Flow Test Results: Flow test results, flow and pressure.

- Maintenance: Any maintenance done and future maintenance required.

- Signatures: Inspector’s and authority’s signature to approve the inspection.

Technology to Make Inspections Easier

Digital Forms and Mobile Devices

Digital forms and mobile devices can make the inspection process easier. Platforms with cloud storage like Google Drive allow inspectors to access, fill and share forms in real time, to increase efficiency and accuracy.

Internet Connection

An internet connection allows real time updates and syncing of inspection data. So all stakeholders have access to the latest information and can respond to any issues found.

Tablets and Computers

Using tablets or computers for inspections allows for easy data entry and storage. Digital forms can have text boxes and fields for all the information needed, making it more user friendly and reducing errors.

Summary

Inspection, testing and maintenance of standpipe systems is critical to fire safety and NFPA compliance. Knowing the types of standpipe systems, their inspection requirements and using technology to make documentation easier, businesses can improve their fire protection and keep their occupants safe. The 2017 standpipe and hose inspection form is a complete form to document the inspections and keep these critical fire protection systems reliable.

Explore More Forms

Fire Door Inspection

Fire Extinguisher Inspection Form

Fire Sprinkler System Inspection Report

System Record Of Inspection And Testing

Emergency Exit Light Inspection Report

Related Forms

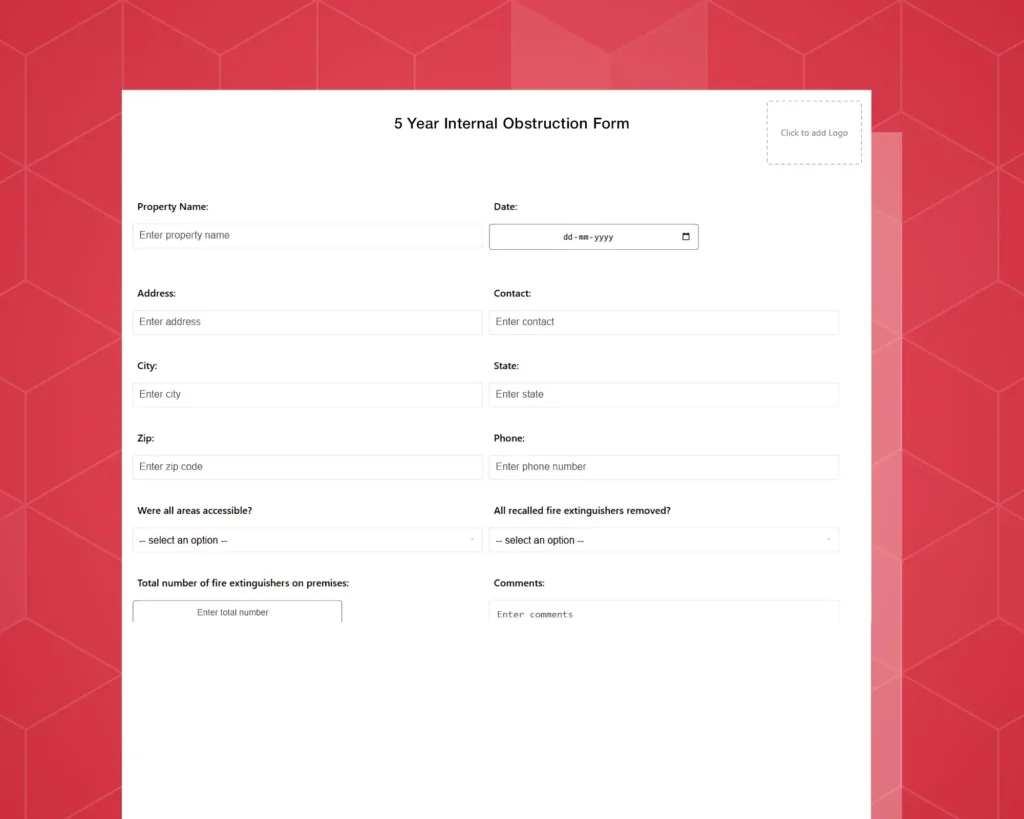

5 Year Internal Obstruction Form

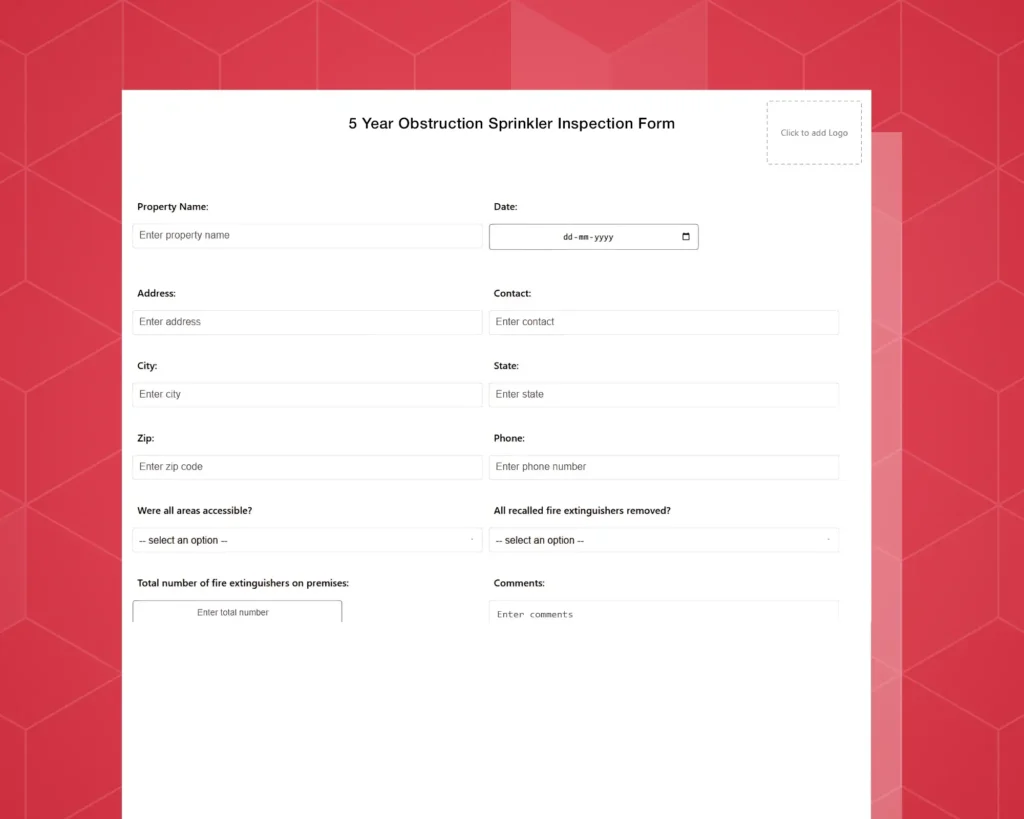

5 Year Obstruction Sprinkler Inspection Form

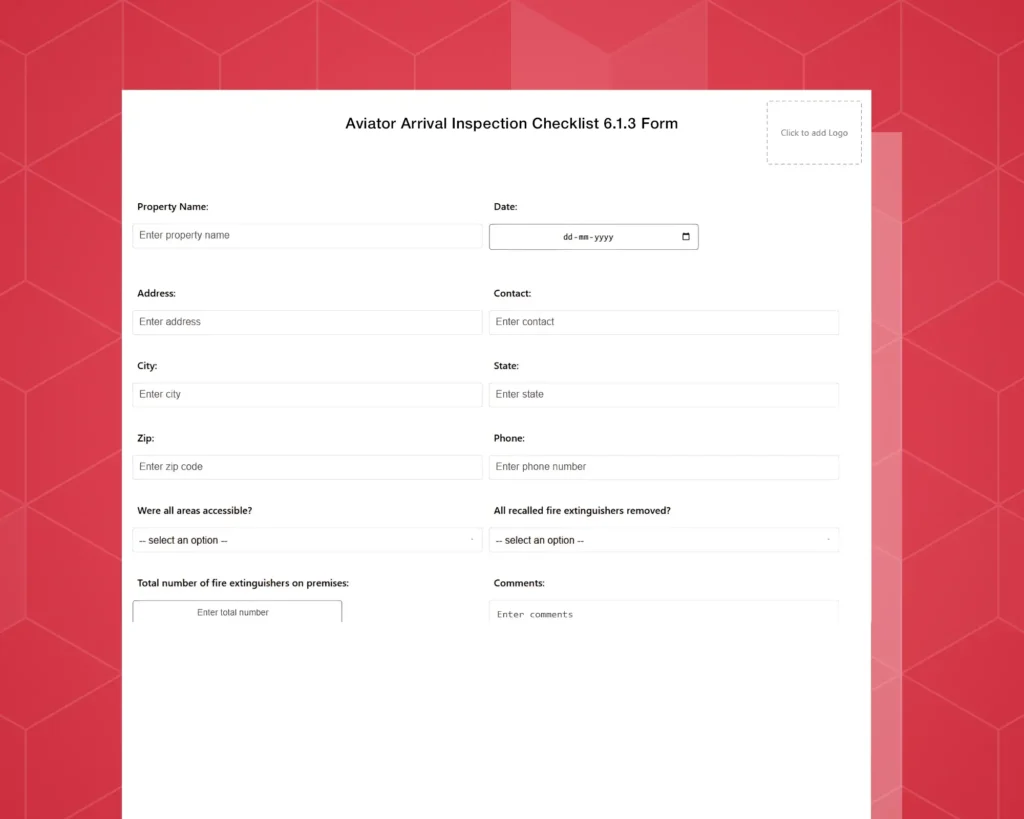

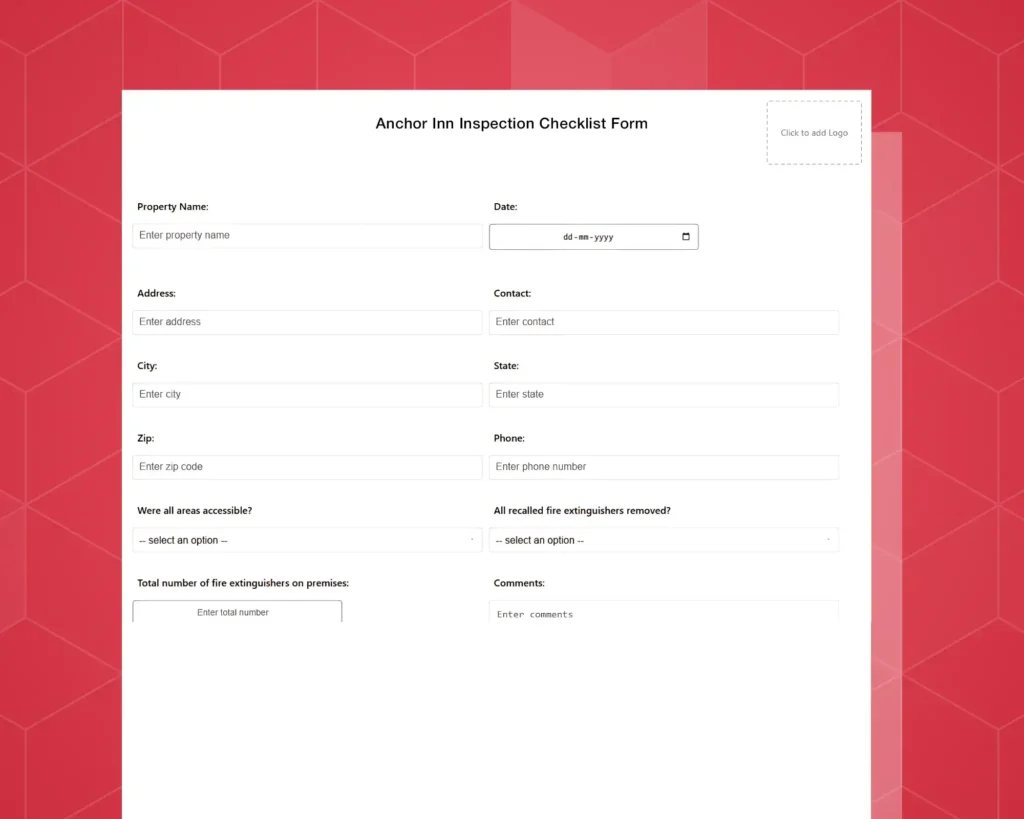

Anchor Inn Inspection Checklist Form