- Fire hydrant provides immediate high-pressure water.

- The main types of fire hydrants: wet barrel and dry barrel.

- Hydrant Colors refers to water flow capacity in GPM.

- NFPA 291 makes regular inspections mandatory with annual visual checks and flow test every 5 years.

- Digital hydrant inspections reduces human error and helps compliance tracking.

Most of us have walked past different colored fire hydrants, standing in the corners of the street. Even though most fire hydrants work simply, they are the most important firefighting equipment. But how do they work?

Fire hydrants are one of the crucial components of any fire suppression system that offers an immediate water supply to the firefighters to control and extinguish fires quickly. This high-pressure water outlet is strategically positioned in cities, townships, and industrial sites to provide immediate response to emergencies. But just positioning fire hydrants is not good enough; they should go along with maintenance, adhere to safety standards, and fully work, or they may fail when most needed.

For fire protection experts, building owners, and municipalities, it is essential to know how fire hydrants operate and are maintained as guaranteed in accordance with fire safety and NFPA standards and avoid any financially punitive penalties for noncompliance. A proper inspection with routine servicing could make the difference between controlling a fire and seeing a horrendous loss.

In this article, we are going to discuss

How a fire hydrant works and its role in firefighting

What are the different types of fire hydrants,

What do the different color schemes of fire hydrants mean,

The main components of a fire hydrant fire system,

How to inspect and maintain a fire hydrant.

Table of Contents

How Does A Fire Hydrant Fire System Work?

Water Supply And Valve Operation For Fire Hydrants

Fire hydrants don’t store water inside them. They help the firefighters to access the water of the city’s underground water supply. So, when they connect their hoses, they get water flow from the city’s largest municipal water mains that are buried beneath the streets.

Municipal Water Supply: The majority of hydrants are connected to the mains of the city water distribution, where a steady flow of pressurized water is assured.

Private Water Systems: Some industrial sites, large estates, or gated communities might have dedicated water tanks or underground reservoirs connected with private hydrants.

A fire hydrant operates an internal valve system for controlling water flow:

By opening the valve on this fire hydrant with a special wrench, the firefighter removes the internal barrier that otherwise prevents pressurized water from rushing into the hydrant.

How The Fire Department Attach Hoses?

The water mains have pressurized water inside them, and when the valve on the hydrant is opened, the high pressure of the water flow lets the firefighters attach their hoses and direct water onto the fire.

In order to activate a hydrant, the firefighters:

Remove the cap of the fire hydrant to connect a firefighting hose to the valve outlet.

Open the main valve to allow water to flow under high pressure.

Control the flow of water with the valve and hose nozzles to provide the best water pressure for firefighting.

Water pressure is usually in the range of 50 to 150 PSI (pounds per square inch), but this may vary according to the location, design of the hydrant system, and municipal supply pressure.

Flow Testing Of Fire Hydrants

Fire hydrants need to be in proper working condition all of the time. What if firefighters arrive at a place and connect their hoses only to find out that the hydrant isn’t working? This is when a continuous flow test comes in handy.

During a flow test, fire officials or city workers:

Attach a pressure gauge to the hydrant.

Open the hydrant valve for static pressure measurements (pressure without any flow).

Observe residual pressure (pressure with flow).

Record flow rate in GPM to ensure that it will be able to supply it fast.

If you want to know more about how to test a hydrant, you can check out our blog on Fire Hydrant Testing Kit.

We are going to discuss the color codes in the other section because color codes help firefighters quickly identify the best hydrant for the job. Without regular inspections, hydrants work inefficiently. If there is a delay in fire suppression, it could lead to an increase in losses.

What Are The Different Types of Fire Hydrants?

The invention of the first modern pillar fire hydrant in the world is credited to Frederick Graff, the chief engineer of the Philadelphia Water Works company, in 1801. It replaced the fire plugs and helped firefighters fight larger fires more efficiently.

In this section, we are going to discuss the two primary types of fire hydrants. They are wet barrel hydrants and dry barrel hydrants.

Wet Barrel Hydrants

Wet barrel hydrants are most common in areas where freezing temperatures are not a concern. In these hydrants, water is always there in the body.

Firefighters can hook up their hoses quickly and get water supply without wasting any extra time.

Features

No temporary water supply: A pond of water sits constantly in the barrel of the hydrant, ensuring the approach is always open during emergencies.

Multiple Outlets: Wet barrel hydrants have multiple valves, and firefighters can supply water in controlled flow into several hoses at once.

Advantages

Firefighters can connect hoses instantly and start fire-fighting operations without being held back by waiting for water to fill up the hydrant, especially during an emergency.

The uncomplicated design helps in easily operating and maintaining these hydrants when used in suitable climates.

Disadvantages

If the weather is very low, then the water that is inside them freezes and expands. The pipes thus burst, and other fire hydrants become useless.

Dry Barrel Hydrants

Dry barrel hydrants are built specifically for those areas where the temperatures are at or below the freezing point and areas where it snows.

These fire hydrants keep the supply water below freeze level just below the ground surface so the water does not freeze in them. The hydrant stays dry until needed.

Features

Underground Valve: There is a valve located below the frost line controlling the water flow so that the water remains below ground level until the hydrant is open.

Drainage: The hydrant allows any residual water from use to drain back to the ground so that there is no water left in the barrel to freeze.

Advantages

Since the water is kept below the freezing level, dry barrel hydrants function appropriately in cold climates without being affected by the frost.

The fire hydrant design reduces hazards due to ice formation, which helps to provide maximum service life.

However, there are still certain disadvantages of this incredible fire hydrant.

After the hydrant has been opened, there is a brief delay before the hydrant water exits from the connection point, as the water must travel from the underground supply.

The internal construction is more complex, which can create a hinderance during maintenance and repair.

Hydrant Type | Description | Best For |

Pillar (Above-Ground) Hydrants | Stands above ground, easy to locate and access | Urban and suburban areas with clear space around streets and sidewalks. |

Flush (Underground) Hydrants | Installed below ground, with a covered access so as not to obstruct | High-traffic areas (for example, airports and industrial areas) where above-ground hydrants pose a hazard. |

What Do The Different Color Fire Hydrants Mean

Fire hydrants are pretty interesting. You see them in various bright colors, standing on the ground and always ready to fight fires.

Each of the colors represents their capacity for water supply. The water supply is measured in gallons per minute. Firefighters can see the colors and determine quickly whether the fire hydrant has enough pressure to tackle fire in houses or large buildings.

Red Fire Hydrants

Red is bold, and it might initially seem that the red fire hydrants are powerful in fighting larger fires. But in the firefighting world, it is lightweight. They provide a water pressure of less than 500 GPM.

They are usually suitable for residential areas characterized by small houses and not larger buildings.

What Do Firefighters Get To Know?

Red fire hydrants have low GPM, so they do not deliver enough water for firefighting in high-rise buildings and large commercial properties. Their main function, therefore, is suited to be used for single-family homes in a low water demand setting.

Red hydrants are commonly found in suburban neighborhoods, rural towns, or smaller residential areas where supply is not as strong.

Firefighters use a special wrench to open fire hydrants, but red hydrants require extra care when using them due to their low water supply.

Orange Fire Hydrants

An orange hydrant means that it is getting the water supply from the public system.

Generally, orange fire hydrants spray water at rates ranging from 500 to 1,000 gallons per minute (GPM). So, they are more powerful than the red flavors.

What Do Firefighters Get To Know?

They know that this fire hydrant is strong enough for residential fires and small commercial buildings but probably slightly weaker for big buildings.

Orange hydrants are normally found in towns and cities and areas buttressed by good municipal waterworks. You can call it the middle child in the family of hydrants. They are not too weak, not too strong, but just perfect.

Green Fire hydrant

Green hydrants deliver water pressure between 1,000 and 1,500 gallons per minute, making them ideal for extinguishing fires in large buildings, apartment complexes, and commercial areas.

They ensure a steady water flow rate sufficient for putting out fires in schools, shopping malls, or large warehouses.

Most green fire hydrants are located near fire stations to guarantee strong water flow during fire emergencies.

Blue Fire Hydrant

It is a firefighter’s dream to find a blue fire hydrant. Blue hydrants have a flow capacity of around 1,500 plus gallons per minute (GPM).

What Do Firefighters Get To Know?

Blue hydrants guarantee a sustained water supply at good pressure for the firefighters with few delays.

Blue hydrants are found in downtown areas, industrial zones, and locations with high water pressure.

Firefighters prefer blue hydrants as they have the fastest and strongest water supply.

What Are The Main Components Of Fire Hydrant System

Bonnet– It protects the top of the fire hydrant and keeps dirt, debris, and water away from the internal components.

Stem-It controls the flow rate of water whenever the firefighting person turns the valve nut

Barrel- It is the main body of the fire hydrant and protects the internal components of the fire hydrant. They can be either wet barrels or dry barrels.

Main Valve- Without this valve, the fire hydrant will continuously leak water. It is like a lock to a door and prevents water from gushing out from the fire hydrant.

Nozzle-Firefighting person attaches their hoses in nozzles to pull out water from the hydrant.

How To Inspect and Maintain Fire Hydrant

Significance of Regular Inspections of Fire Hydrants

Test that the hydrants work and deliver enough water pressure.

Detect minor problems with corrosion, leaks, or mechanical failures before they become serious ones.

Preclude violations of NFPA standards and local fire codes.

Protect you against liabilities and penalties in case of non-compliance.

Inspection Requirements Set by NFPA for Fire Hydrants (NFPA 291)

Visual Inspections (Annually): Check for visible damage, blocked flow paths, and missing caps.

Flow Testing (Every 5 Years): Pressure and discharge capacity of water.

Lubrication & Drainage Testing: Verify the operability of all moving parts & ensure drainage thereafter.

Color Code for Fire Department: Hydrants would be painted based on the availability of flow rates.

Non-compliance against NFPA 291 could mean hefty fines, claims against your insurance, or even legal action against you should such hydrant fail during fire emergencies.

Common Problems Seen During Fire Hydrant Inspection

Corrosion and rust weaken its structure and let it seep.

Leaks and defective valves lead to loss of water pressure.

Vehicles, landscaping, or debris may block access to the hydrant.

Frozen and stuck valves frequently occur in cold climates on dry barrel hydrants.

Low or fluctuating flow points to municipal problems or internal destruction with the hydrant.

How Businesses Can Improve Fire Hydrant Inspections

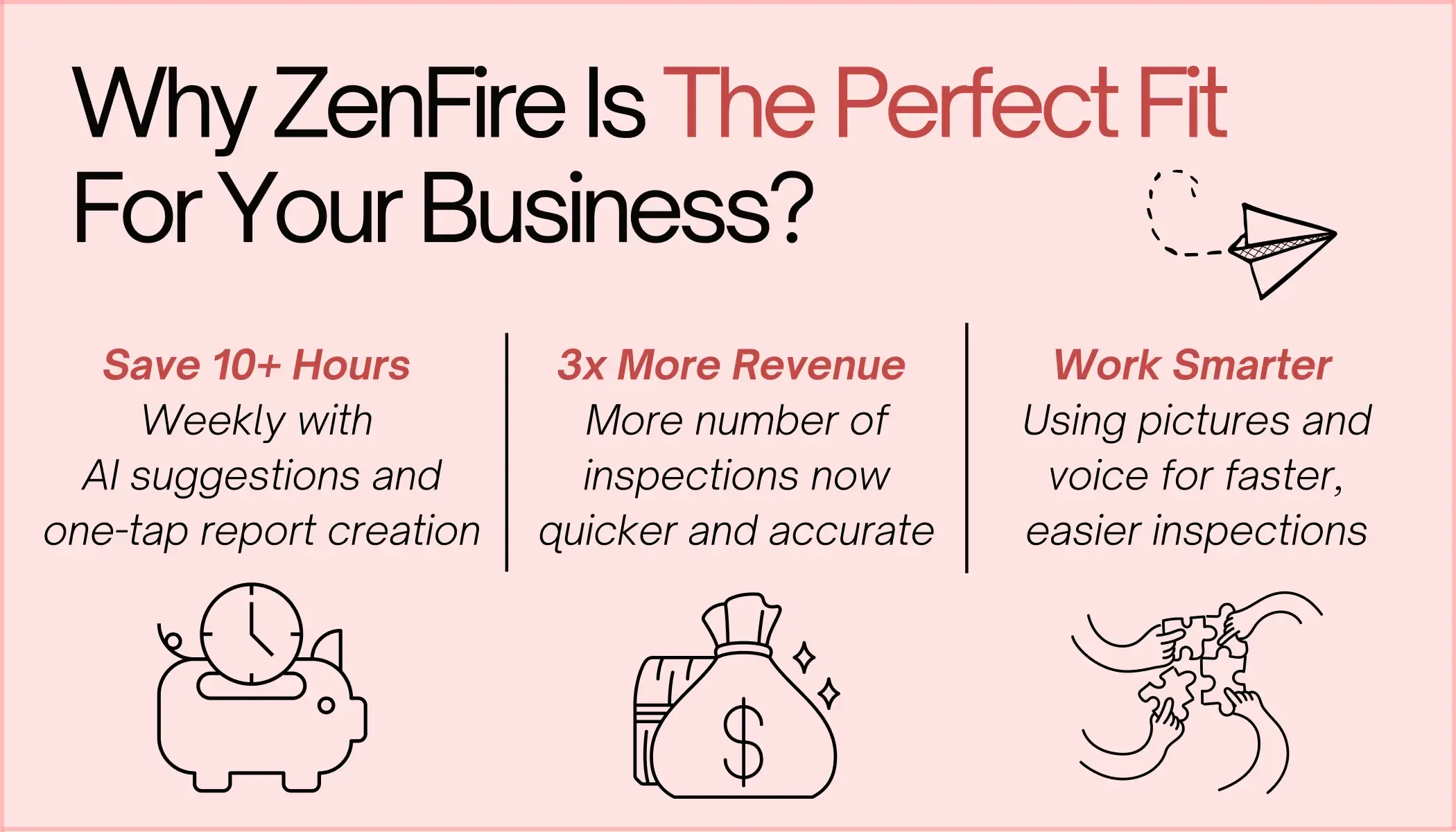

ZenFire assists fire departments, municipalities, and property managers in performing efficient hydrant inspections by replacing standard paperwork with real-time digital tracking.

Our software logs inspection results, tracks water pressure, identifies malfunctioning hydrants, and ensures compliance with standard operating procedures and regulations. It acts as a monitoring system.

With the use of historical data and automated reminders, ZenFire stimulates proactive maintenance and prevents failure. It improves fire safety. Firefighters get immediate access to hydrant conditions, ensuring the best hydrant is used during a fire. It is just like smart hydrants sending status updates.

Why not make it easier and get on a free personalized demo with us?

Get Insights Delivered Straight

To Your Inbox!

Related Reading

Why Your Field Software Management Software Needs QuickBooks Integration

ZenTrades Why Your Field Service Management Software Needs QuickBooks Integration Read More Request Demo...

Read MoreZenTrades How To Manage Electrical Service Agreements Like...

Read MoreZenTrades The Best 5 Jobber Alternatives In 2023...

Read More