- Missed weekly churn tests & poor documentation cause most fire pump failures.

- NFPA 25 mandates weekly, monthly & annual testing of fire pumps.

- Manual logs are error-prone & time-consuming.

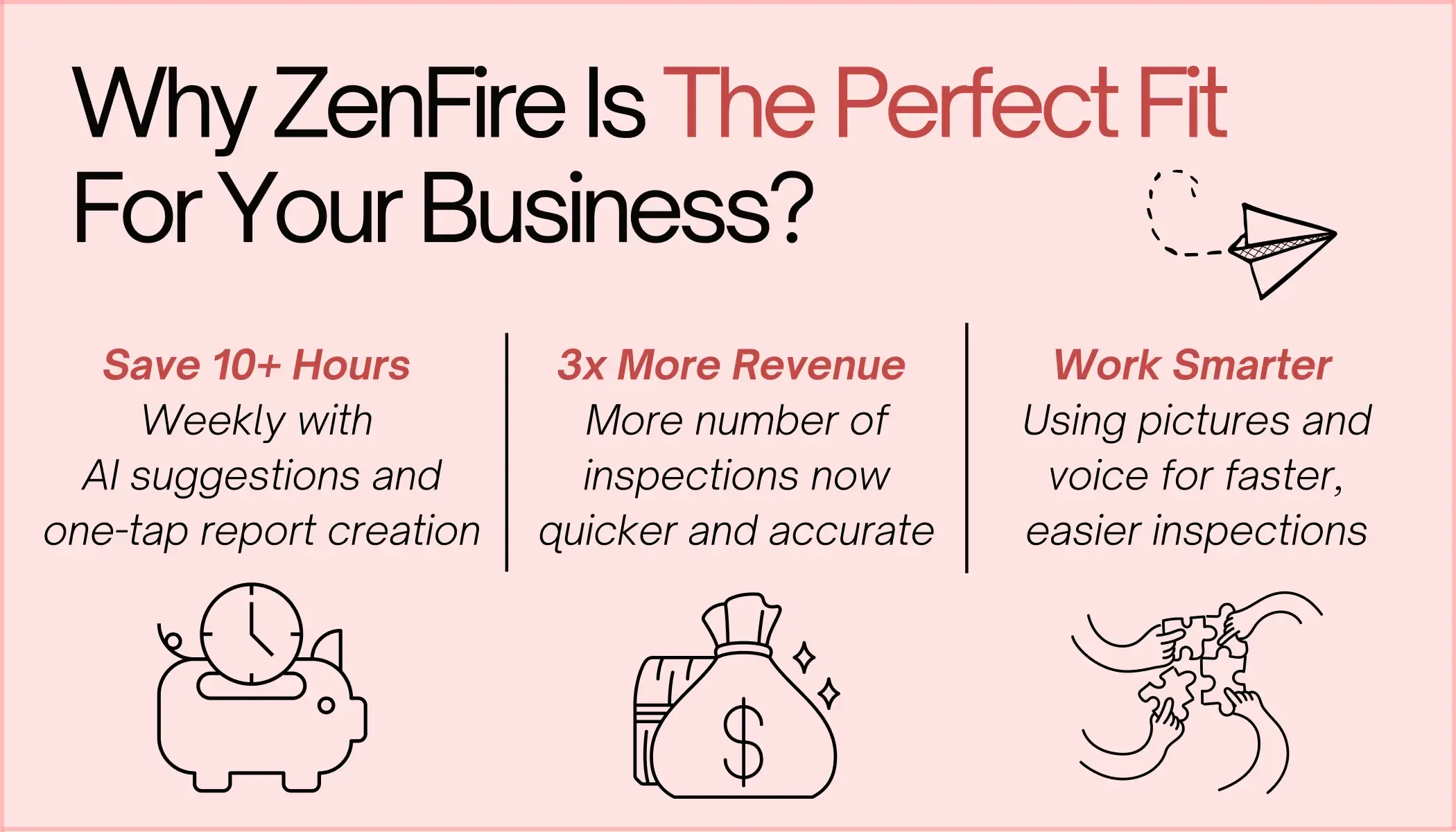

- ZenFire automates scheduling, estimating & deficiency reporting.

- Pre-built digital checklists & templates improve accuracy during inspection.

You don’t need another reminder that fire pump inspections are important because you are the one in the field, week after week. And you are the one making sure that the water properly surges upward in high-rise buildings to protect the occupants on the top floors when fire occurs, because many fire sprinkler systems depend on fire pumps to keep the water flowing. According to NFPA (National Fire Protection Association), a significant number of impairments in fire protection systems are due to missed inspections, poor audit logs, or systems not being tested properly under real-world conditions. And yes, a fire pump might pass a visual inspection, but what will happen when you are called to answer for a failed annual flow test or explain to the AHJ why there was no documented record of weekly churn tests?

Most of the time, the reasons behind fire pumps not working are missed weekly tests, fire pump controller issues, or suction supply problems. The thing is that you already know these things, you already know what is required. You have read NFPA 25 cover to cover. You have run annual flow tests, logged weekly churns, and found misaligned couplings more times than you can count. So, the challenge is not the knowledge. It is the execution, especially when you are managing multiple sites, teams, and inspection frequency cycles, and still trying to keep legally compliant documentation and reports.

The fire safety industry is going through a paradigm shift, a shift towards not just better hardware but towards better documentation, smarter workflows, and automated compliance. ZenFire understands the challenges a professional like you faces daily, and we are here to keep you compliant, consistent, and confident that the fire pumps you inspected are going to work when they need to. That’s why we have provided digital solutions like automated scheduling, dispatching, offline capabilities, NFPA 25-compliant templates, cloud-based storage of client histories, automated deficiency reports, smart documentation, photo tagging, and much more.

Schedule a free demo with ZenFire today to simplify fire pump inspections and your entire fire safety business operations!

In this blog, we are going to walk you through fire pump testing according to NFPA 25, and how digital tools can simplify the way fire safety professionals like you handle compliance.

Table of Contents

Fire Pump Testing Requirements

Inspection is only half the battle to ensure optimal fire pump performance. Testing is where the rubber meets the road because you have made sure that the pump casing, the impeller, the controller, the gauges, and other fire pump components are all in place, but until and unless the fire pump kicks in and works the way it should, it won’t meet the sprinkler system demand during a fire emergency. That’s why NFPA 25 has outlined the fire pump testing requirements and schedule clearly, which includes weekly fire pump inspections and no-flow test, monthly inspection depending on the system type, and annual fire pump flow test. Let’s go through each of them:

Weekly Churn or No Flow Test

Weekly fire pump inspection and testing are like a health check of the system. You just have to run the pump without flowing water and make sure it starts and runs smoothly without any trouble, like abnormal noises, pressure spikes, or any controller or electric motor issues. For example, in an electric pump, you need to start the test from the controller, let it run for at least 10 minutes, and record the suction and discharge pressure, RPM, and amp draw. However, if the system is a diesel pump, then you need to run it for at least 30 minutes.

Monthly Fire Pump Test

Even though NFPA 25 doesn’t require a separate monthly check for most facilities’ fire pumps, diesel fire pump systems need monthly inspection because batteries and fuel systems are involved. You just need to check if the batteries are sulfated, or the fuel tank is corroded, or not. Just physically open and check battery terminals and electrolyte levels, and confirm that the fuel levels are at or above ¾ full and free from contamination.

Annual Full Flow Test

Conducting annual fire pump tests is crucial because you can’t conclude that a fire pump will meet the demand just because it turns on; you also need to make sure that it hits 100%, 150%, and shutoff conditions according to the manufacturer’s specifications and NFPA 25. This is because if the fire pump fails and can’t maintain the water pressure during a fire emergency, then the people and property will be at risk.

You just need to connect flow meters or discharge hoses to a remote fire pump test header, flow water through calibrated devices to simulate the system demand, and make sure that there is sufficient pressure at no flow, 100% rated flow, and 150% flow.

Automatic Transfer Switch Testing For Electric Fire Pumps

If the fire pump systems have an automatic transfer switch (ATS), then you need to verify if it can switch power during an outage. You just need to disconnect the normal power supply under controlled conditions, confirm that the switch transfers load to emergency power, and that the pump is running.

Common Challenges With Fire Pump Inspection

If you have been in the fire protection industry for a long time, especially if you are working with stationary pumps like diesel and electric pumps, you know that there are bigger risks than the ones found in a fire pump room. These risks are in those paper forms, spreadsheets, follow-up emails that never got sent, and missed weekly churn tests because the schedule was too overwhelming.

Here are some of the challenges that most inspectors and fire contractors face during fire pump inspections:

Poor Documentation

Manual documentation during a fire pump inspection can feel like documenting in a minefield. You have to be in a loud fire pump room with a diesel engine rattling, and you are trying to record suction pressure, churn pressure, flow readings, battery voltage, and whatnot. Amidst this chaos, there’s a high chance you are gonna write something wrong or even miss one. These little mistakes can create big problems, especially if you are comparing the test results against a fire pump performance curve or submitting for a fire department or safety audit. Additionally, photos of deficiencies are stored in someone’s personal phone, which makes it more difficult to create a proper report.

Missed Inspections

If you are managing multiple sites, then there’s a high chance of missing an inspection because not all facilities will have weekly churn tests on the same day, nor would they have annual fire pump performance tests in the same month. Sometimes, inspections also get postponed due to bad weather or a technician not coming to work that day. Oftentimes, it can also become difficult to track the last inspection date and the service history for all clients. All these things add up, resulting in some pumps going without a churn test for several weeks.

Difficulty in Tracking Follow-Ups or Repairs

Sometimes, deficiencies like insufficient flow from circulation relief valves, busted gauges, and worn controller relays are not followed up on, and the issue gets buried under 20 other inspections. The order should go like this: inspection is completed, a deficiency is identified, a repair schedule is created, and the follow-up is done. But there is no centralized tracking system, and you always end up relying on spreadsheets, mail threads, or just memory.

No Central Record Of Past Test Services

When scheduling an inspection or trying to know what happened in the last inspection for a particular client, using spreadsheets and paper is very time-consuming and daunting. Moreover, if you want to piece together five years of fire pump test results from paper folders, then it is really very painful, especially if a stationary fire pump is having a recurring pressure drop issue.

The Digital Tools That Simplify Fire Pump Inspection

If you really have a discussion with your fire technicians, you would find that at least one of your technicians might have gone to an old facility that had a fire pump installed in the back with barely enough light to read the pressure gauge. They might have had their paper checklist on a clipboard, a phone flashlight in their mouth, and a pen in their other hand. And by the time they got back to the office, they couldn’t remember whether the relief valve was leaking or not because a part of the documentation was smudged.

The thing is that if your operational and technician teams are still hauling paper forms, emailing scattered PDFs, or manually reminding themselves of the next fire pump performance test, then there is a high probability of losing clients and revenue, missing inspections, and suffering liability issues, especially in this era of AI and growing technology where there are fire inspection softwares like ZenFire out there to automate entire fire safety businesses.

Scheduling and Automated Reminders

Fire pump inspectors have to struggle a lot. They have to conduct weekly churn tests, monthly controller checks, annual fire pump performance curve validation with a flow meter, and all three points on the curve. It’s understandable that some of the things might slip through the cracks. With ZenFire, you can automatically schedule inspections and assign them to each of your technicians beforehand. You can also assign recurring fire pump inspections based on NFPA 25 requirements for monthly, quarterly, and yearly inspections. Your technicians can use the ZenFire mobile app, which works on both iOS and Android, to look through the services that are assigned for that day, and can even click on the last controller check or rated flow test date, previous flow test results, along with the service history. This way, you also don’t have to worry about missing a deadline again.

Pre-Built NFPA-25 Compliant Forms and Checklist

Most of the time, the frustrating thing about inspection is struggling through different forms and checklists for all types of fire pump systems, like electric and diesel pumps. ZenFire has pre-built NFPA 25-compliant forms and checklists that you can easily customize according to your local regulations. Whether your technician is logging churn pressure, suction pressure, or verifying if the pump is meeting the necessary pressure for sprinkler system demand, these in-built forms have all the necessary input fields. It’s like having an entire codebook built into your workflow.

Attach Photos and Texts During Documentation

If there is a leaking circulation relief valve, it is always better to take photos rather than just text to put it in the deficiency report. But most of the time, the inspector either writes the deficiency or takes photos with their personal phones, which might get lost under the photos of other fire pump inspections. With the ZenFire app, they can directly take a photo from the app and add a caption to the photo during documentation, which they can automatically generate into a legally compliant report with embedded photos, your business logo, and a digital signature. Additionally, with our voice-to-text functionality, your technician can just speak throughout the inspection, which will automatically be added as text during the fire pump inspection.

Offline Mode Because Pump Housings Are Not Always Wi-Fi Friendly

Fire pump rooms are not always wi-fi friendly, and simply because of internet issues, the inspections might stop halfway, which can delay other services scheduled for the day. ZenFire app supports offline mode and makes sure that your fire technicians don’t face any blockers during the inspection. They can complete the full inspection offline, and once they are back in the region with stable internet, all the data is synced automatically.

Cloud-Based Storage Of Inspection History and Reports

Searching the historical flow and pressure data of a particular client’s fire pump or inspection reports of the past five years in spreadsheets and Dropbox folders is very frustrating and time-consuming. With ZenFire, everything is stored in the cloud, and you can pull up any inspection report and review it in seconds or send it to the client whenever they ask for it.

Smart Dispatching

Dispatching fire technicians can become quite an overwhelming and daunting task, especially when there are emergency calls. With ZenFire’s smart dispatching feature, you can view the real-time location of any technician and schedule the nearest one for emergency services based on the job priority in an efficient and cost-effective way.

Conclusion

Fire pump inspections and testing are complex and demanding. And on top of these, your inspectors don’t need the added pressure of chasing down paperwork, fixing someone else’s missed follow-ups by sacrificing theirs, or collecting the five years of inspection history from a folder or separate spreadsheets. Most of the time, fire pump inspections fail because fire safety businesses are not able to keep up with the modern demands of scheduling and compliance.

You and your team are already doing the hard part of making sure that fire pump inspections are working when they are required the most, but you also need to do the smart part of digitizing these inspections with a fire inspection software like ZenFire.

Schedule a free demo with us today and see how fire pump compliance becomes as easy as walking in the park.

Get Insights Delivered Straight

To Your Inbox!

Related Reading

Why Your Field Software Management Software Needs QuickBooks Integration

ZenTrades Why Your Field Service Management Software Needs QuickBooks Integration Read More Request Demo...

Read MoreZenTrades How To Manage Electrical Service Agreements Like...

Read MoreZenTrades The Best 5 Jobber Alternatives In 2023...

Read More