- Hydrant Colors refers to water flow capacity in GPM.

- NFPA 291 standardize color coding for immediate fire response.

- Fire hydrants are uniquely painted in some cities for ownership and aesthetics

- Hydrant Maintenance prevents color from fading and improves response time.

- Smart Hydrant Monitoring Software improves hydrant inspections and compliance tracking

Colors have always spoken stories without words. The same applies to the fire hydrant color codes. You get to know everything about them, be it their residual pressure, group flow capacity, and even who owns it based on the color with which the fire hydrants are painted. For firefighters, the colors are for rapid identification of certain factors that will help them in firefighting during an emergency.

If you are also inquisitive about colored fire hydrants, their history, and how the color coding system says so much about them, then this article is perfect to quench your thirst.

In this article, we are going to take you through

The history of public fire hydrants and their colors

NFPA Guidelines For Fire Hydrant Color Coding

How Fire Hydrant Improves Fire Safety And Response Times

Why are fire hydrants uniquely painted in some cities?

Best Practice For Hydrant Maintenance

Table of Contents

History Of The Public Fire Hydrant Color Code

When Were The First Fire Hydrant Invented?

Before 1800, fire hydrants were not a common thing to see on public streets. Firefighters used fire plugs and formed a bucket brigade to fight fires. It was a very hectic and inefficient process of fire protection.

Around the 1800s, Frederick Graff, the chief engineer of Philadelphia Water Works Company, took matters in hand and invented the first pillar fire hydrants to improve fire safety and help fire departments fight large fires more efficiently so there would be less loss.

When The First Fire Hydrant Didn’t Have A Color

The first fire hydrant was made of cast iron or bronze. And it used to be unpainted and blended well with the urban landscape. They were not even coated with the same color. Since there was no standardized color coding, firefighters found it difficult to know the rated capacity of the water flow provided by the hydrant until they connected their hoses to the nozzle caps.

So, if there was a large fire and the water pressure provided by the fire hydrant was too weak to fight the fire, then it became dangerous and slowed down the process of firefighting.

Standardization Of Fire Hydrant Colors

After a century (around the 20th century), when the cities started to expand, and the firefighting techniques started improving, people began to realize that a proper color coding system was required to improve the quality of fire protection. Towns started coloring the public fire hydrants with bright colors so that they don’t blend with the landscape and become more visible.

Till then, fire hydrants were colored randomly and didn’t have a proper and standardized color coding system. But still, there were some cities that started experimenting with some colors (people who are as inquisitive as you about colors) so that they could identify how much water the particular hydrant offered.

Around the 1950s, NFPA recommended certain guidelines in order to standardize the public fire hydrant colors all over the United States. These guidelines helped fire departments evaluate the rated capacity of how much water supply hydrants offered. This improved fire safety as more cities adopted the guidelines over time.

NFPA Guidelines For Fire Hydrant Color Code

Till now, we have read about the magic of colored fire hydrants, what the first fire hydrant looked like, and why there was a shift to standardization of how should the fire hydrants be colored.

The bold colors do make the hydrant attractive, but there’s more to it. NFPA 291 is a guideline book that was created by NFPA. It details the color coding of fire hydrants, and this helps the firefighters assess the flow rate of water supply during emergencies.

However, there are some cities that are lenient with the colors at the owner’s discretion if it’s the case of private fire hydrants.

In the upcoming sections, we are going to look at the NFPA recommendations and why these matter for public street safety, firefighting efficiency, and even urban planning in places like San Francisco and the rest of the world.

NFPA 291- Color Code

If there’s a large fire in a residential area, and a firefighter connects his hose to the nozzle cap just to find out that the water flow is so low that it can’t put out a small backyard fire.

If hydrants are painted correctly, then the firefighter can immediately identify the square-inch water flow rate and water pressure. It decreases the time wasted in guessing whether the hydrant has enough rated capacity

Whatever is outlined in NFPA 291 guidelines, it is actually a straightforward color coding system for fire hydrants. And even though private fire hydrants’ color may differ based on the owner’s discretion, the standard system is based on gallons per minute (gpm).

Blue (More than 1,500 GPM)

Blue-colored hydrants offer the highest water flow rate of more than 1,500 GPM. They are used in major fire operations that need a very good flow to extinguish fire.

Green (1,000-1,499 GPM)

Green-colored hydrants give a strong rated capacity in the range of 1,000 to 1,499 gpm or gallons per minute. They are a perfect hydrant to put out fires in residential areas and high-risk zones.

Orange (500-999 GPM)

Orange-colored hydrants, or some call them chrome yellow hydrants, give a moderate rated capacity between 500-999 gallons per minute (gpm). Chrome yellow is a reflective paint.

Red (Less than 500 GPM)

The fire hydrant barrels that are coated with red provide a limited flow of water less than 500 GPM.

Color | Flow Rate | Expect Flow Test Results |

Red | Low Flow | Under 500 GPM |

Orange | Medium Flow | 500 GPM- 999 GPM |

Green | High Flow | 1000 GPM-1499 GPM |

Blue | Very High Flow | 1500+ GPM |

How Fire Hydrant Colors Improve Fire Safety And Response Times

Fire hydrant color coding is essential for emergency response so that firefighters can quickly learn about water availability and use it to execute fire incidents. Proper and systematic identification of hydrants is imperative for the proper procedure of firefighting activities.

The Importance of Accurate Color Coding for Firefighters in Choosing the Right Hydrant

Firefighters in emergency conditions use hydrant colors to determine the water flow rate available to them in Gallons Per Minute (GPM). This measure provides information on which hydrant can provide enough water to put out a fire. For example, blue hydrants indicate high flow (more than 1500 GPM) for big fires; red hydrants indicate low flow (500 GPM and below) appropriate for small incidents. Being able to identify these colors quickly allows them to deploy resources effectively, thus minimizing the response time.

Types of Consistent Hydrant Painting and Maintenance Effects

Over time, the weather climate, vandalism, and general wear affect hydrant colors, which can ultimately lead to being misidentified in an emergency. To avert this, regular maintenance is mandatory:

Regular Scheduled Repainting: Municipal authorities should define a schedule for repainting hydrants for such events.

Clear Communication: In cases where hydrants have been artistically painted for events in a community, it is much more important to keep the bonnet color standard to show the right size and flow capacity of the water main. For instance, the East Aurora Fire Department experienced problems from adding decorative paint onto bonnets and creating other issues with regard to that at the time of emergencies.

Use of Reflective Materials: Paint reflective zoom tape should be added in order to increase the visibility of hydrants, especially during dark when fast locating and evaluating the hydrant capabilities is crucial for firefighters.

Case Studies: The Impact of Hydrant Misidentification on Fire Response Times

Case 1: Decoration-based Misidentification

In East Aurora, hydrants were artistically transformed in local festivals where artists keep changing their colors on bonnets. Important information about the water main size underneath every hydrant gets distorted through this. In emergencies, firefighters are required to refer to maps to find hydrants’ capabilities, hence the delay in response time.

Case 2: This has slowed the response to an emergency resulting from a proper parking arrangement.

Cars parked over yellow ‘H’ signs denoting hydrants underground inhibited firefighters from accessing vital water supplies during emergencies. This has caused a delay in establishing water supply lines. This calls for public awareness and proper signage to ensure hydrant access.

Who Actually Decides The Hydrant Color?

Even though NFPA 291 guidelines have a recommended standard for colors for fire hydrants, these colors may vary from municipality to municipality.

Local and private owners, as the case may be, may determine different colors for their particular hydrants as per their requirements or other guidelines. San Francisco for example, has hydrants colored in some unusual colors to make them blend into the historical districts or comply with the municipal policies.

For some cities, different colors are applicable to private fire hydrants. Mostly, these hydrants are located on private properties like industrial sites, business parks, or gated communities, painted red or all-black to indicate their status as hydrants not publicly available. Some areas incorporate purple hydrants into their repertoire to designate non-potable water that relies on recirculated or untreated water sources.

In short, if you do happen to find a hydrant that is painted completely different from the usual NFPA 291 colors, there is a strong chance it could be an adjustment made by their respective property owner.

Fire Flow Testing Of Hydrants

Fire flow testing is important as it helps you make sure that the hydrant is providing the correct water flow rate.

It is a simple test where the person will open the hydrant and check the water flow rate of the hydrant using special tools. And if the calculated capacity doesn’t meet the expectation, then hydrants are either cleaned, replaced or connected to some other water supply source.

Why Fire Hydrants Are Painted Uniquely In Some Cities?

Although NFPA provides guidelines on color coding systems for fire hydrants, certain cities disregard the recommended practice. These cities have fire hydrants painted with different colors, such as silver or white, to denote their ownership. These colors exist outside of the four classes of color schemes that NFPA recommends.

For instance, particular hydrants connected to a public water supply are painted yellow or white. Private hydrants might be painted red, purple, or black. In certain regions, public hydrants supplied by non-potable water are painted purple, thus indicating that water is unsafe for drinking.

There are areas where the fire hydrant bodies are painted uniquely based on that municipality’s aesthetic. For instance, the archetypal hydrant bodies in some locales within Honolulu have also been painted silver with a blue top to fit the tropical backdrop of the town. Then, in Boston, hydrant bodies are painted black with a red hydrant top. The color for fire hydrant bodies has been chosen to match the vintage style of the historic districts.

Fire Hydrant Maintenance Best Practices

Routine Inspection and Schedule for Repainting to Maintain Visibility

Fire hydrants are exposed to extreme weather, environmental wear, and abuse every moment. Subsequently, the paint fades, rust develops, and mechanical components wear out. When hydrants become inoperable due to poor maintenance, firefighters would typically experience a delay in getting access to a reliable source of water when it counts.

Establish quarterly or annual routine inspection schedules to assess hydrant condition, water pressure, and overall functionality.

Repaint hydrants according to NFPA 291 and local ordinances to make sure they are still visible.

Apply rust-resistant coatings and reflective paint to improve visibility, especially in low-light conditions.

Ensure fire hydrants are not obstructed by parked vehicles, vegetation, or debris.

Some municipalities have GIS-enabled hydrant tracking systems that give flat maps of hydrant locations and keep track of repainting schedules, among other things.

Smart Monitoring Tools to Collect Hydrant Water Pressure and Condition Data

Conventionally, hydrant performance has been checked by humans visiting the site to observe their condition. This method is prone to error. With the modernization of IoT and real-time monitoring, cities begin to track hydrant conditions without human intervention, thus enhancing the safety and security of their individuals during times of disaster.

Pressure sensors give an instantaneous flow of hydrant water use, with falls or unexpected pressure changes.

Improves the efforts of authorities using smartphone leak detection technology, as well as old methods in identifying leaks within the pipe system or through unauthorized hydrant access.

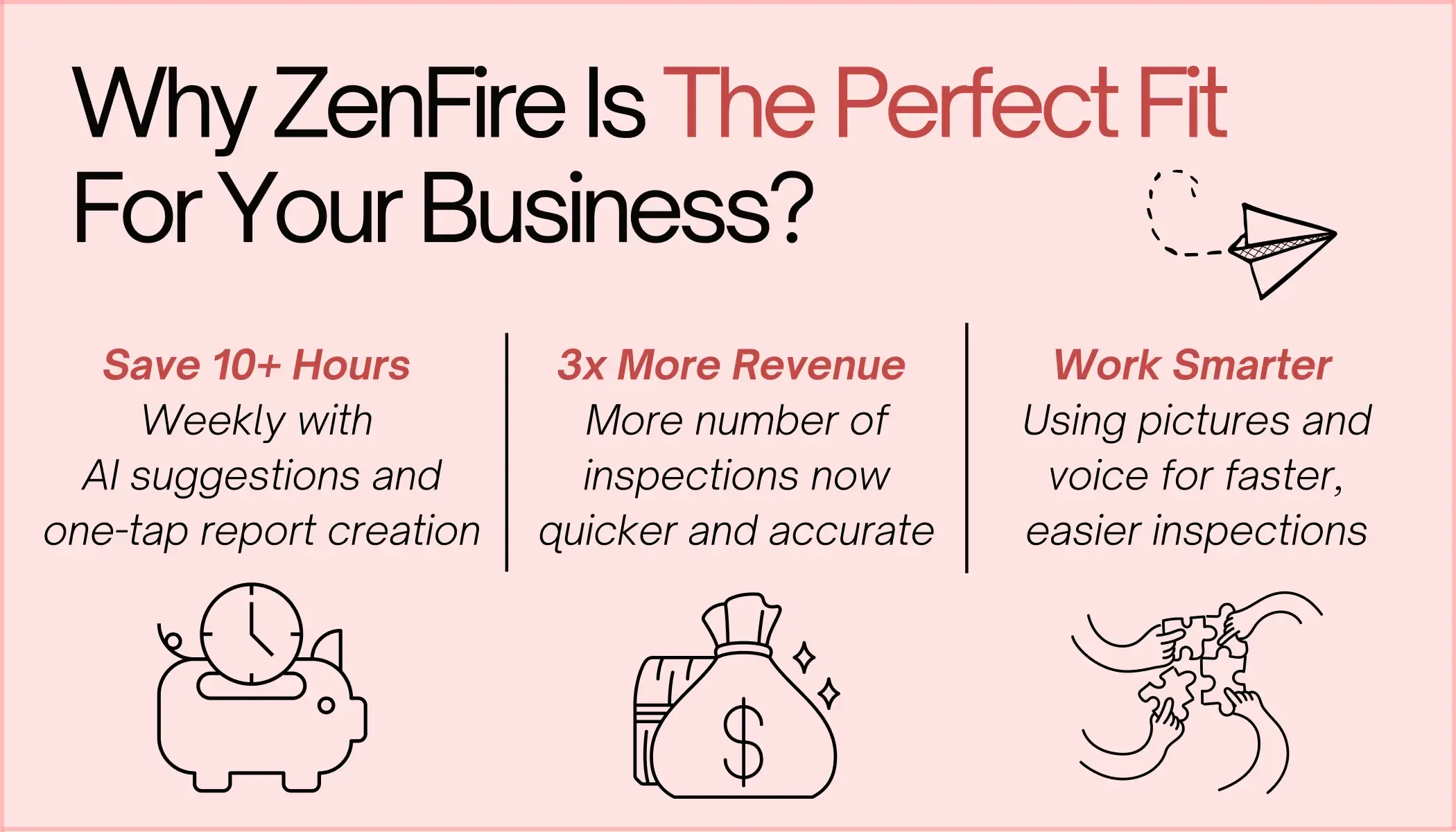

Additional software like ZenFire would alert fire agencies and facility managers whenever a hydrant is in disrepair through monitoring from the cloud.

Most municipalities subscribe to AI-powered fire safety platforms that provide predictive maintenance insights, and hydrants remain operational before failing to meet an emergency.

Partnering with Fire Safety Platforms to Automate Hydrant Inspection Tracking

Manual recording of hydrant inspections/maintenance logs often turns out delayed, lost, and out of compliance with regulations. With automated fire safety platforms like ZenFire, fire departments can better record in-field inspections, file compliance reports, and manage proactive maintenance scheduling.

Access to mobile-friendly inspection software like ZenFire would allow field teams to update the hydrant status in real-time.

Hydrant maintenance logs should be automated to store the inspection history, repairs, and upcoming dates and times of service.

GPS-based hydrant tracking would improve response times and ensure firefighters can get the nearest access to a working hydrant in the case of an emergency.

Many organizations are turning to cloud or future-based compliance tracking with such fire departments, allowing hydrant inspections to be entered digitally and generating regulatory reports, thus ensuring that every hydrant remains operable in its jurisdiction.

Conclusion

Proper fire hydrant color coding is essential as it helps firefighters quickly identify precisely what hydrant to use during an emergency while ensuring they access the necessary water supply. Regular maintenance, following NFPA guidelines, and using the latest tracking technologies prevent misidentification, improve response times, and reduce the risk of fires.

Standardized hydrant color codes ensure relevance for municipal authorities, facility managers, property owners, and so on about compliance and preparedness during emergencies. Inspections, repaintings, and real-time hydrant monitoring can guarantee that this lifesaving resource stays optimally functional to save lives when it is needed most.

While fire safety technology is continuously evolving, smart fire safety solution now equips cities and organizations with automated hydrant tracking, digital inspection logs, and real-time condition reporting, thus making maintenance effortless and enabling compliance. Get a free demo with us to automate fire hydrant testing.

Get Insights Delivered Straight

To Your Inbox!

Related Reading

Why Your Field Software Management Software Needs QuickBooks Integration

ZenTrades Why Your Field Service Management Software Needs QuickBooks Integration Read More Request Demo...

Read MoreZenTrades How To Manage Electrical Service Agreements Like...

Read MoreZenTrades The Best 5 Jobber Alternatives In 2023...

Read More