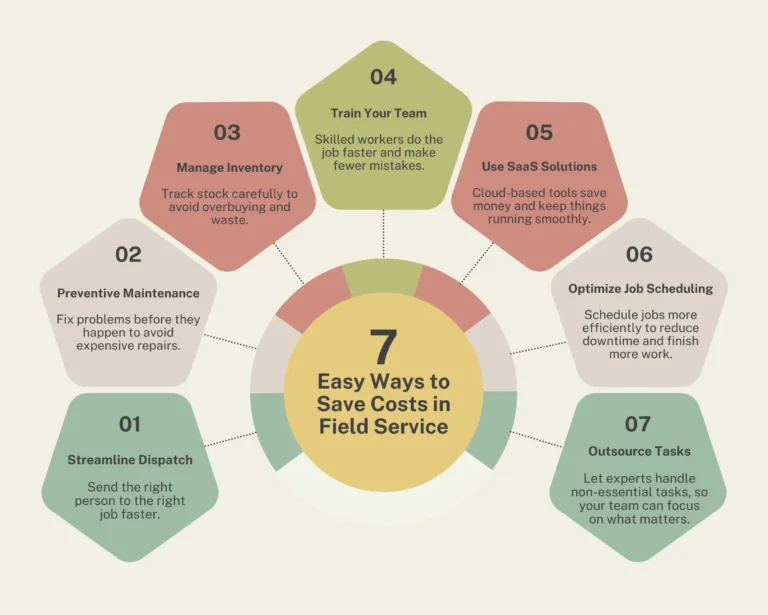

7 Cost Control Strategies for Field Service Operations

- Private Equity

When operating a field service business, you’re not just managing tasks in the field. You are multitasking a ton, including dispatching teams, managing assets and equipment, or responding to emergency service requests. You oversee a delicate balance of resources, time, and money, where every decision impacts the bottom line.

For investors, PE firms, and business owners in the field service landscape, this is done by bringing efficiency to cost control.

In this blog post, we will explore practical strategies for reducing unnecessary costs, which can make a real difference in the daily operations of your business. We will also cover some tips on getting the most out of your team and technicians without spending too much or exhausting your budget.

Here What We Cover

Strategies For Cost Control In Field Service

Streamlining Dispatch

Have you ever faced a situation where one of your technicians is stuck in traffic on the way to the job site? On the other hand, another technician who had wrapped up his job was near this client and could have handled the job easily instead.

If not, then these situations are more common than you think. Even though they might seem small and insignificant, they can accumulate into massive time and cost inefficiency.

Now, what if you could optimize and automate your dispatch operations in a way that always sends the right person to the right job site? It will know where your technicians are, the jobs they are suited for, and the best person to minimize the downtime in between. When your dispatching system is smart and enables fuel cost savings, it increases technician productivity and efficiency. Labor hours are utilized more efficiently, which increases customer satisfaction levels.

How to Implement: You can use route optimization tools integrated with field management software. This can help ensure that you’re taking effective steps to cut unnecessary travel costs and save fuel. An automated dispatch system can easily be set up and optimized to assign jobs based on proximity, availability, and skills.

Proactive Maintenance

Reactive or customer-driven maintenance is now a thing of the past. Waiting for customers to report a malfunction or system servicing has been replaced by proactive maintenance methods. The reason is that reactive maintenance could be unpredictable and contribute to downtime. In contrast, proactive maintenance is smarter and more logical, increases customer satisfaction, and provides a better way to provide maintenance services overall.

Maintaining equipment before it breaks down can reduce unexpected downtime and avoid the high costs of emergency repairs. This can enable your units to perform better and for a longer duration of time without eating up your wallet.

How to implement: Having robust field service management software (FSM) at your fingertips can help set an efficient maintenance schedule and send reminders to your team, this automation helps in creating personalize customer interaction, which helps boost sale. Using analytics to track equipment data and usage insights can help predict timeframes for potential maintenance requirements. It can help ensure that nothing slips through the cracks and everything is serviced before it’s too late. Over the course of time, the reduced breakdowns will lead to more uptime, signifying fewer loss of hours and increased productivity.

Inventory Management

Stocking assets and equipment may initially seem like a smart idea, but it can lead to chaos and mismanagement in the long run. Every unit sitting on the shelf represents a capital that could have been invested elsewhere. On the other hand, if you don’t have critical parts stocked up, you can lose out on potential service opportunities, which can lead to cost delays.

So, what can be done to strike the perfect balance?

The key is to make inventory management smarter and more efficient. By tracking usage patterns and predicting demand, you can easily optimize your inventory and stock units that are deemed essential based on your data. Maintaining the right amount of stock can keep your operations running smoothly without investing too much in unnecessary parts.

How to implement: you can leverage inventory management tools that easily integrate with your field service management software. This way, you can keep a tab on your inventory and garner useful insights such as what’s in stock, which parts need to be restocked soon, and much more. These systems can help you automatically check your inventory at a glance and automatically reorder supplies when your inventory reaches a certain threshold. Now, you can always ensure that you never over-order or fall short of your required equipment.

Training And Upskilling

Field service companies often underestimate the power of training and upskilling their technicians. A well-trained technician can bring in more profits and showcase better productivity than an undertrained staff. Technicians who have upskilled themselves during their service, have a history completing jobs faster, diagnosing problems more accurately, and provide better resolutions and customer service.

Investing in continuous training and upskilling opportunities for your technicians isn’t just about ticking the box to enable business growth; it’s a strategic imperative to make yourself stand apart from the competition. It can also help showcase to your customers that you genuinely care about providing them with the best service possible. Moreover, it can also help you make your workforce more efficient and make your services more valuable. Training can help cut down costly mistakes, and when handled by an upskilled workforce, more complex jobs can be handled, reducing the need for outside contractors.

How to implement: You can build and enable a culture of learning and healthy competition within your company. Utilizing online training modules, mentorship programs, and certification incentives can not only help you upskill your technicians but also make your employees feel that you care about them. When technicians are equipped with the latest skills and knowledge of advanced tools, they work smarter, reduce costly errors, and contribute to your bottom line.

Get posts like this in your inbox.

Keep learning how to run a 5-star business with our bi-weekly newsletter.

SaaS Solutions For Data-Driven Decision Making

Depending on data-driven insights is always a good idea because they’re quantitative. They shove raw facts in your face, which, if understood and strategized accordingly, can yield amazing results for your business. The real challenge, however, lies in capturing these data sets. Capturing, organizing, and making sense of it — that is what businesses need to utilize the data effectively.

Field service businesses usually sit on large datasets that are valuable and can help them align their operations in a way that can prove profitable in the long run. From job completion to collecting payments and extending maintenance contracts — all of this can be optimized and better strategized to boost profitability, increase upselling and cross-selling of services, and increase customer satisfaction levels.

The right software, undoubtedly, can help you make this process more efficient and swift by turning data into insights that help reduce costs. For instance, when tracking fuel expenses and consumption, data can reveal patterns suggesting efficient routes, or monitoring job durations can pinpoint bottlenecks in the process. These metrics can help you make informed decisions in your business, directly impacting the bottom line.

How to implement: investing in SaaS software that is tailored specifically for field service businesses can initially be a strategic move. Check out some best field service management software for small businesses, to make better decision.. These platforms offer interactive and comprehensive dashboards, helping you look at your operations at a glance. These dashboards break down your data into actionable insights, pinpointing deficiencies and inefficiencies and suggesting measures to address them. The result is operational costs are reduced, an increased efficiency in business processes, and better use of resources.

Job Scheduling Optimization

Optimizing your technician scheduling helps you avoid the biggest cost-incurring factor in your business. How? When your schedule is not optimized, you are enabling downtime—the hours that are wasted due to technicians waiting around between jobs and assignments. In the field service business, idle time is expensive, especially when you are paying for labor, vehicles, and equipment that are not being utilized at the moment.

When your scheduling process is optimized, it ensures that jobs are distributed evenly throughout the day and helps minimize periods of inactivity. This helps save a lot of money and also improves job satisfaction among technicians who prefer staying productive and busy throughout their work hours.

How to implement: You can integrate scheduling software with your field service business management software, which allows you to make changes in real time. So, in cases where a job runs for longer durations or a technician finishes their job early, you can easily reassign tasks on the move. This way, you always keep your team productive and reduce downtime costs, improving revenue and profit margins.

Outsourcing Tasks

Even though it might come off as counterintuitive to speak about outsourcing in a blog that talks about cost control, certain tasks and functions are better off being outsourced. The key is to know when outsourcing provides a better value and when it does not.

Outsourcing non-essential tasks can help you focus on what you do best while letting the experts handle the rest. Moreover, outsourcing comes with predictable pricing models, making it easier to budget.

How to implement: Assess and review your business operations and look for areas that can be outsourced. Essentially, this can lead to cost savings and free up technicians’ time. Make sure that you compare the costs of doing these tasks in-house versus by an external provider. If beneficial, outsourcing can be a viable option, helping you reduce overhead costs and improve efficiency.

Keeping Costs Under Control

Field service businesses are undoubtedly complex. However, controlling costs doesn’t have to be. Focusing on core strategies like dispatch management, effective training and upskilling of technicians, enabling proactive maintenance and inventory management optimization, and embracing technology, etc., can help you keep your operations running and make them more efficient. Its all about making smarter choices that help increase your profit margins, enhance productivity and revenue by making dollar worth without sacrificing on the service quality.

Explore a better way to grow your business. Book a free demo now!

Get organized, win jobs, and wow customers.

Book A Free Demo with ZenTrades Today!

Related Reading

ZenFire 7 Cost Control Strategies for Field Service Operations Request...

Read MoreZenFire Personalizing Customer Interactions in Field Service Operations Request Demo...

Read MoreZenFire A Strategic Guide For PE Firms To Maximizing Portfolio...

Read MoreZenFire How IoT Will Impact The Future of Field Service...

Read More